Back

THE REASON FOR THE INVESTOR AND CONTRACTOR CHOOSE QH PLUS Q-WELDED MESH

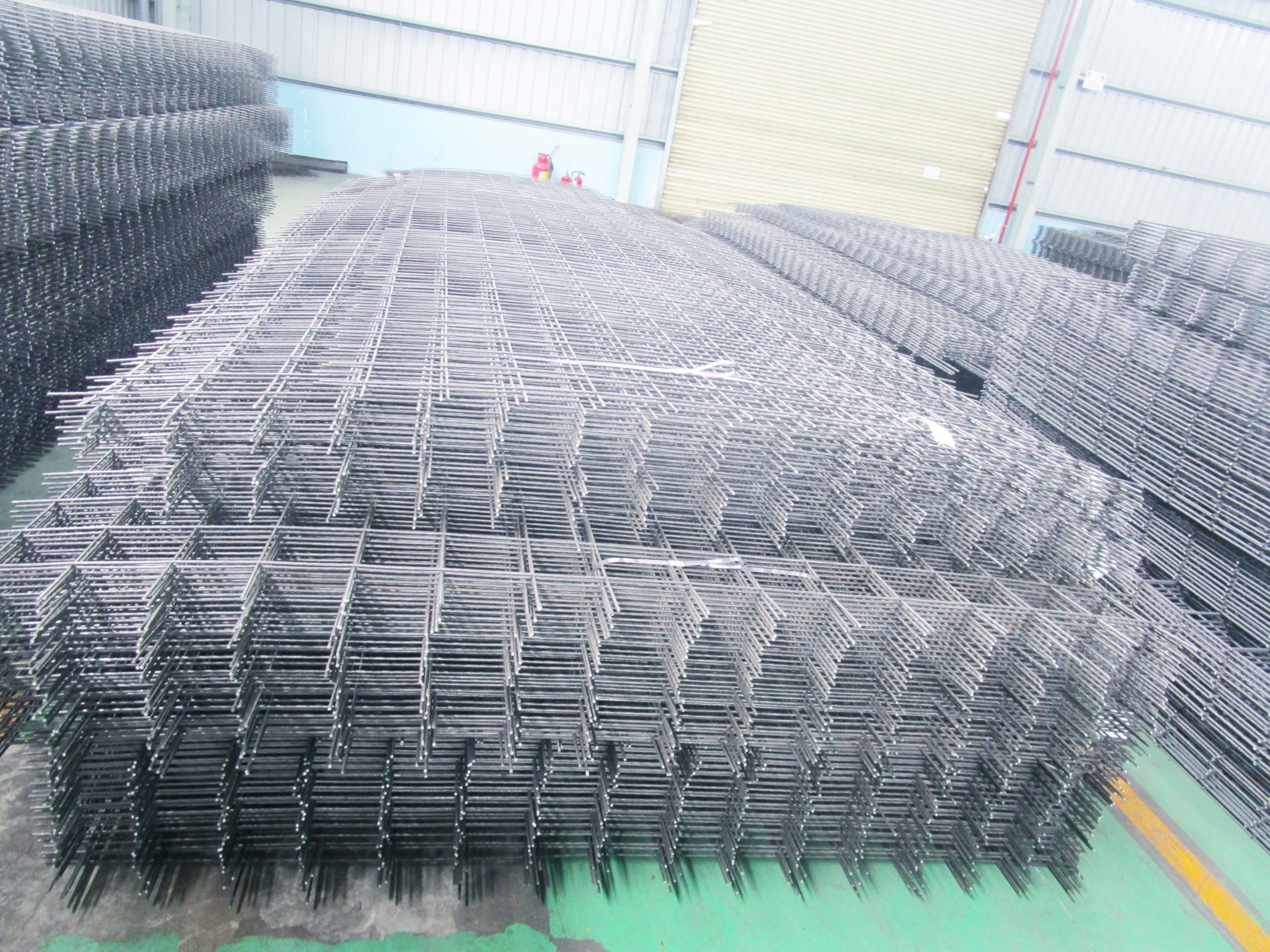

WHAT IS Q-WELDED MESH?

Welded mesh is a mesh made of ribbed or plain wire rods. These steel wire rods must undergo the resistive spot welding technology. At this time, steel will meltdown to the point that steel wires connect together, thus forming a dense, consistent mesh into a big slab.

(Image: QH Plus Q-Welded Mesh)

WHY IS WELDED MESH?

Replacing hand-woven steel mesh with welded mesh helped contractors save considerable construction costs and improve work quality.

Galvanized welded mesh is manufactured from the high-tensile cold drawn wire rods and welded bu resistive spot welding technology. This ensures the steel wires are distributed evenly along the joint and not affected by its intensity, meeting TCVN 9391:2012 standard and Quacert QCVN 7:2011/BKHCN national certificate.

(Image: QH PLUS Q-Welded Mesh product and making process)

Besides, the main advantages of welded mesh to contractors as well as investors are:

- Saving time and financial costs.

- Meet the needs of customers in size, type of steel (plain or ribbed).

- Further, the use of welded mesh also ensures high accuracy because all stages have been programmed on machines and will ensure the progress of supplying products to contractors and investors.

- The use of welded mesh or galvanized welded mesh also claim the professionalism of contractor with investor, minimize costs as well as supervise works.

- Finally, the transport of welded mesh is also easier than the transport of materials to the construction area and begin to make wire mesh by manual method.

The above points are just a few of the outstanding advantages of Q-Welded Mesh supplied by QH Plus JSC. QH Plus is committed to provide high quality welded mesh, keep up with the progress, and meet customer needs.

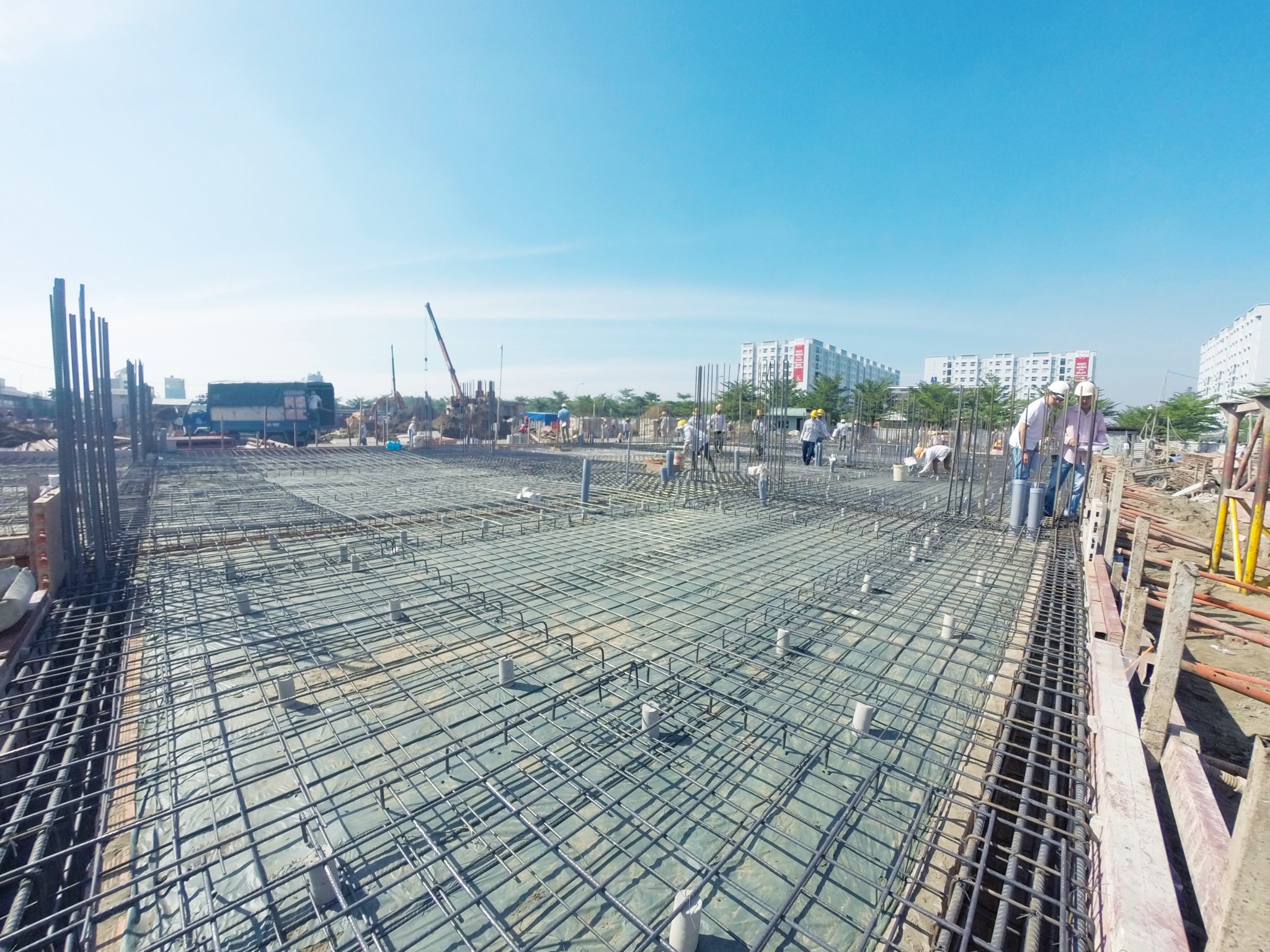

The application of Q-welded mesh, galvanized welded mesh of QH Plus JSC is also very diverse, such as:

- High rise floors, factory floors

- Concrete wall

- Pool

- Concrete road,...

(Image: Q-Welded Mesh Application)

For further instructions of product information, please contact Hotline 0832-000-666